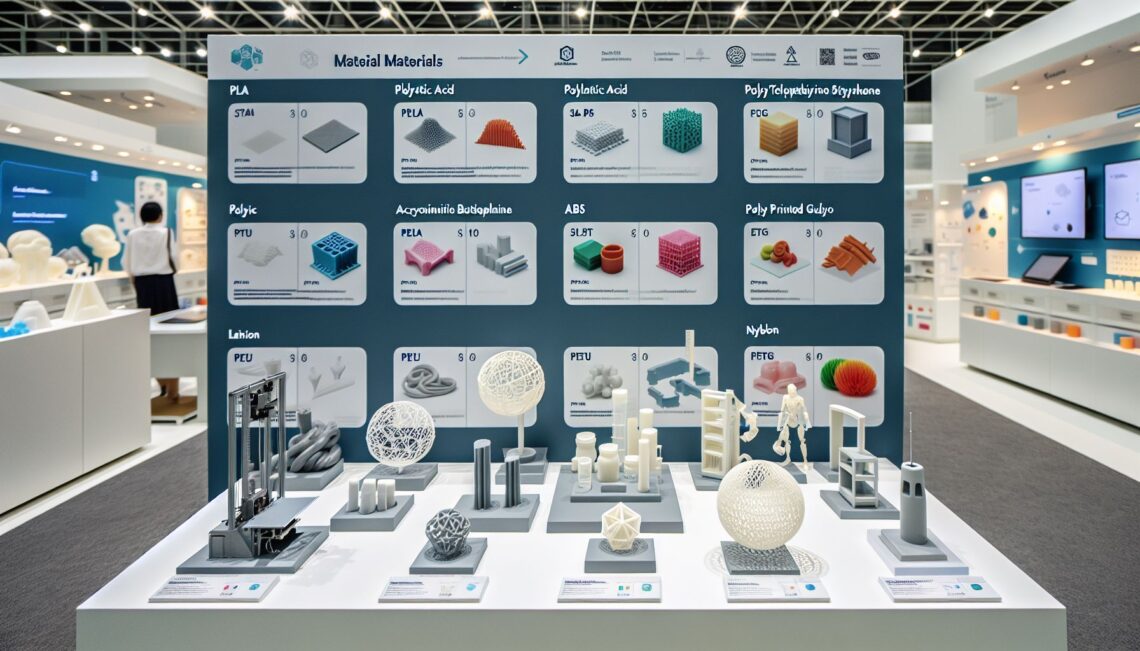

Exploring the Materials Used in 3D Printing for Adult Objects

In recent years, 3D printing has revolutionized the manufacturing industry, opening up a world of possibilities for creating complex and customized objects. While once limited to prototyping and niche applications, the technology has gained widespread popularity, making it accessible to consumers and professionals alike. A crucial aspect of 3D printing lies in the materials used, which determine the strength, durability, and aesthetic properties of the final product. In this article, we will delve into the various materials used in 3D printing for adult objects and explore their unique characteristics.

The Versatile PLA – Polylactic Acid

Polylactic Acid (PLA) stands out as one of the most commonly used materials in 3D printing. Derived from renewable resources such as corn starch or sugarcane, PLA provides an environmentally friendly alternative to traditional petroleum-based plastics. Not only eco-friendly, but PLA also offers a broad range of colors, making it ideal for creating visually appealing objects.

PLA is known for its ease of use and excellent printability. It has a low melting point, allowing for smoother extrusion and reducing the risk of nozzle clogging. However, it is worth noting that PLA might not be the best choice for functional parts that require high heat resistance or mechanical strength.

The Mighty ABS – Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene (ABS) is another widely used material in 3D printing. Known for its exceptional strength, durability, and heat resistance, ABS is commonly employed in producing functional objects that undergo high-stress conditions.

One of the remarkable aspects of ABS is its ability to withstand high temperatures without warping, making it suitable for objects that come into contact with hot liquids or environments. Its durability also allows for greater flexibility during post-processing, as ABS can be sanded, glued, or painted to achieve the desired finish.

Nevertheless, ABS does have some drawbacks. One significant consideration is its fumes, which can be potentially harmful if not properly ventilated. Additionally, due to its higher printing temperature requirements, ABS might not be compatible with all 3D printers.

The Resilient PETG – Polyethylene Terephthalate Glycol

Polyethylene Terephthalate Glycol (PETG) is a relatively newer entrant in the world of 3D printing materials but has already gained substantial popularity among enthusiasts and professionals. Combining the advantages of both PLA and ABS, PETG offers an ideal balance of strength, flexibility, and heat resistance.

One of the key benefits of PETG is its excellent layer adhesion, resulting in enhanced durability and impact resistance. Its ability to withstand higher temperatures than PLA while avoiding the fumes associated with ABS makes it a safe and reliable choice for producing functional prototypes and end-use objects such as mechanical parts or household items.

Furthermore, PETG is highly transparent and comes in a variety of vibrant colors, allowing for the creation of visually captivating objects that retain their clarity and vividness.

Exploring Advanced Materials and Techniques

Beyond the conventional PLA, ABS, and PETG, researchers and 3D printing enthusiasts continually explore advanced materials and techniques to expand the application possibilities even further. These advancements include:

-

Nylon: Offering exceptional strength, durability, and flexibility, nylon is often used in functional and mechanical parts that require resistance to impact and wear.

-

Metal Filaments: By combining plastic binders with metal powder, it is now possible to 3D print objects that exhibit metallic properties. Metal filaments like steel, copper, or bronze open up a whole new realm of possibilities for creating decorative, functional, or artistic pieces.

-

Resin-based Photopolymer: Photopolymer resins, cured using ultraviolet (UV) light, enable the production of highly detailed and precise objects. These resins are favored for their ability to produce smooth surfaces and intricate designs, making them ideal for jewelry, dental models, and custom figurines.

Conclusion

The materials used in 3D printing play a crucial role in determining the functionality, strength, and overall aesthetics of the final objects. While PLA, ABS, and PETG are widely employed for their reliable properties, advancements in material science continue to push the boundaries of what is possible with this transformative technology. As research continues and new materials are developed, 3D printing promises to revolutionize numerous industries, inspiring creativity and transforming the way we manufacture and consume adult objects.

You May Also Like

Enhancing Learning and Creativity: Exploring the Possibilities of 3D Modeling and 3D Printing in College Education

December 17, 2023

Now is the Time to Learn How to Print with a 3D Printer: A Guide for College Students

February 3, 2024